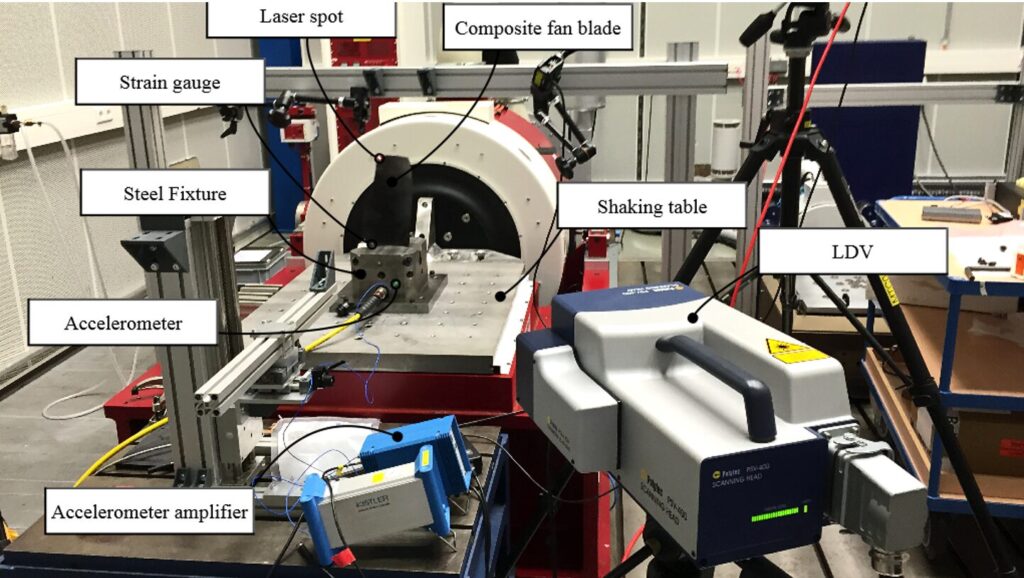

XCTE covers many composite fatigue testing applications from coupon to fullscale level. In this test case, a scaled composite fan blade is tested using XCTE high frequency technology to detect the onset of fatigue delamination. The surface temperature, the frequency response phase, and base acceleration traces detect the change in structural compliance caused by the damage onset. In the next image, the test setup is shown.

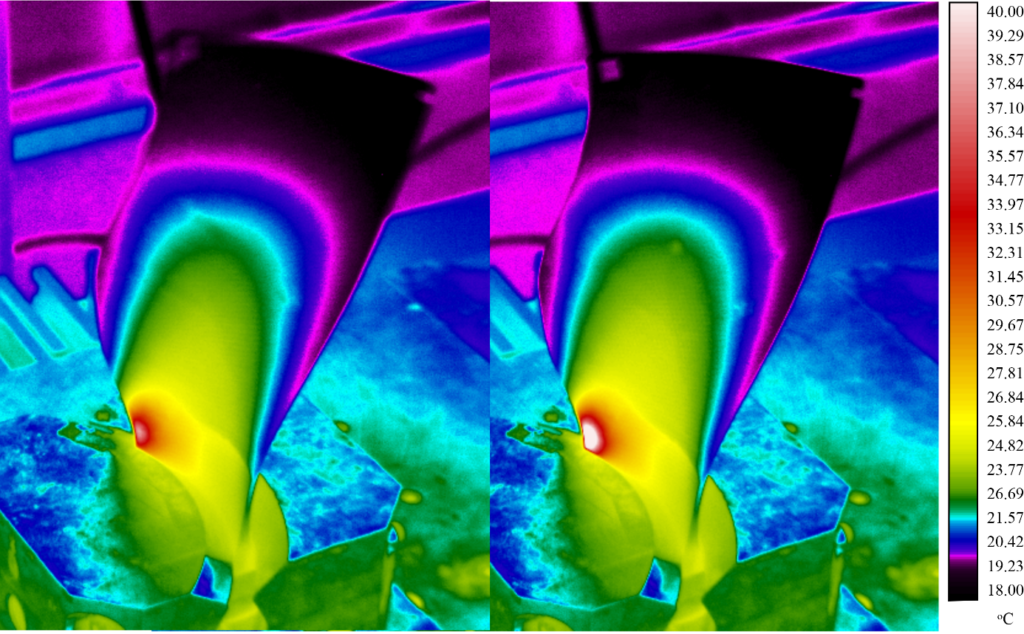

From the thermal images, it can be seen that a hot spot is generated in which fatigue damage occurs.

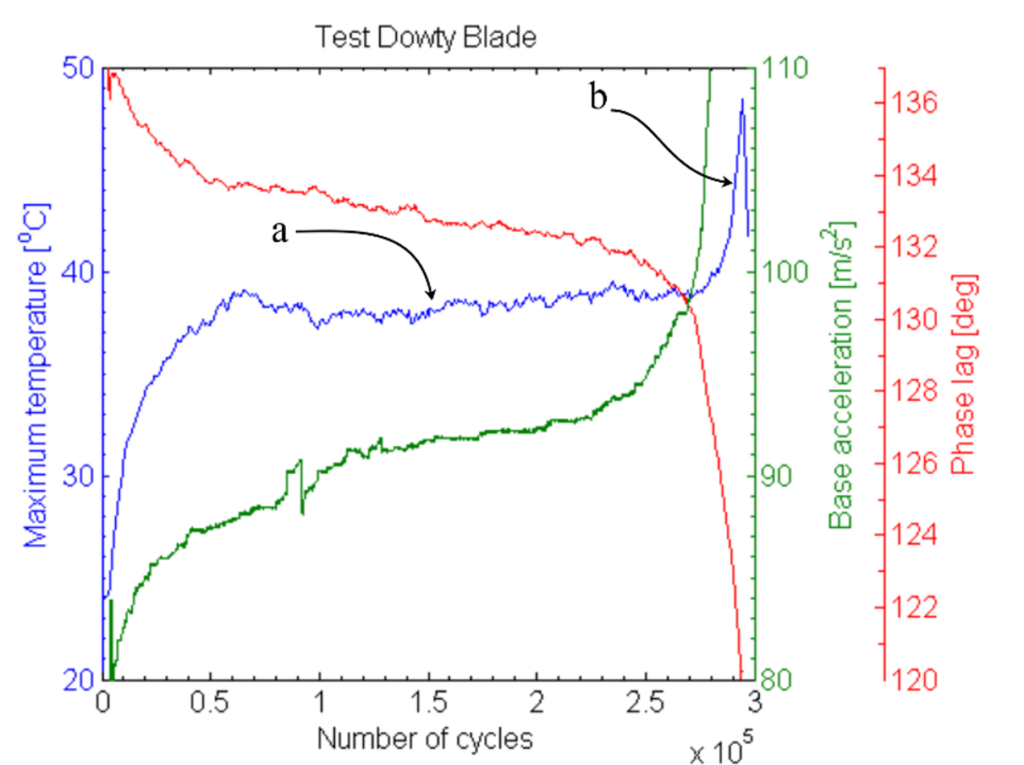

During the excitation, the following output is generated: surface temperature, phase decay and base acceleration.

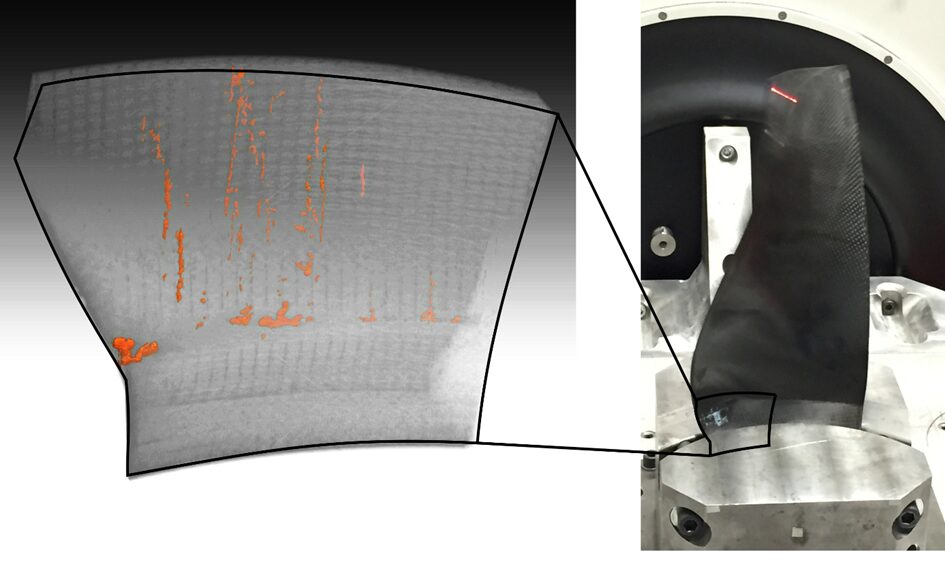

To validate if there is indeed damage occuring in the hot spot, an X-ray measurement is done at this location. The X-ray measurement shows the damage in the area of the temperature hot spot. Because of the high testing frequency of 155Hz, the test of 300,000 cycles was finished in 53 minutes.

Get in touch with us!

Have questions about our technology or services? We’re here to help!